Circular Economy in Mining: The Hidden Treasures of Mining Waste

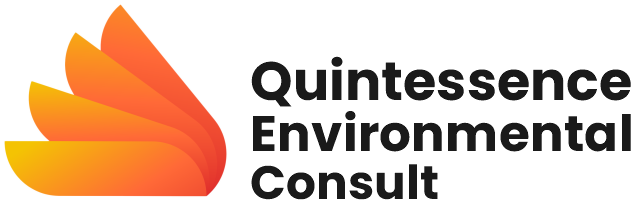

KEY TAKEAWAYS: Circular Economy Concept in Mining: The article highlights the shift from the traditional ‘take-make-waste’ model to a circular economy in mining, where waste is reused, recycled, and regenerated. Nigeria’s Mining Waste Challenge: Mining activities in Nigeria, particularly artisanal operations, generate significant waste that exacerbates environmental issues such as land degradation, water pollution, and health risks. Economic Opportunities in Recycling Mining Waste: Repurposing mining waste offers various benefits, such as using tailings in construction, recovering valuable minerals like rare earth elements and lithium, and treating mine water for agricultural use. Global Inspiration for Nigeria: Examples from countries like Australia and Canada illustrate how mining waste recycling can contribute to sustainable practices. Australia converts tailings into industrial bricks, while Canada focuses on extracting critical minerals from waste to support clean energy transitions. Call for Policy and Innovation: The article advocates for stringent regulations, investment in advanced technologies like bioleaching, public-private partnerships, and educational initiatives. INTRODUCTION Our nation Nigeria, although partially dependent on mining explorations for its economic growth has a pressing challenge that remains largely overlooked. Mining Waste is a hidden untapped treasure that could revolutionize our economy whilst protecting the environment. Hence, the concept of a circular economy in mining, whereby waste transformed into wealth, reduces environmental hazards, and fosters sustainability. WHAT EXACTLY IS A CIRCULAR ECONOMY IN MINING? A circular economy moves away from the traditional ‘take-make-waste’ model. Instead of discarding resources after use, materials are reused, recycled, and regenerated (Yiqing Zhao et al., 2011). In mining, this means utilizing waste products as valuable resources. Mining waste typically includes rocks, tailings, slags, and water contaminated during mineral extraction. While these materials have historically been abandoned or disregarded, advancements in technology and sustainable practices now allow them to be repurposed for economic and environmental gain. Imagine a Nigeria where the mountains of tailings from artisanal mining sites become raw materials for construction such as Bricks, Concrete, Foam ceramic and so on. NIGERIA’S MINING WASTE PROBLEM: A GROWING CONCERN Nigeria’s mining sector is expanding, particularly with activities in gold, lead, zinc, lithium, and other minerals. However, unregulated mining, especially artisanal mining generates an immense amount of waste and improper disposal exacerbates land degradation, water pollution, and health risks. In states like Zamfara, Niger, and Plateau, massive dumps of mining tailings dot the landscape, posing serious health risks due to heavy metals like lead, cadmium, and arsenic causing the death of Over 400 children due to exposure to lead-contaminated dust from artisanal gold mining waste (BBC News, 2010). Similarly, in Plateau State, abandoned tin mines have left behind pits that accumulate contaminated water, posing long-term environmental and public health risks (Ogundiran & Osibanjo, 2009). Take a look at the numerous granite quarries spread throughout the country, their inert waste has been classified on the European List of Waste under code 01 04 13, “wastes from stone cutting and sawing other than those mentioned in 01 04 07” (European Comission, 2000). It has a heavy environmental impact due to its adverse effect on soil permeability, for it hinders water seepage to the lower layers, which in turn affects aquifer recovery and plant life. It also constitutes a risk to human health due to the small percentage of crystalline silica in the fines which, if inhaled, may cause lung disease of varying severity (Singh et al., 2016). TRANSFORMING MINING WASTE INTO ECONOMIC OPPORTUNITY Recycling Tailings for Construction and Infrastructure The mining circular economy promotes sustainable practices by recycling and repurposing mining waste and byproducts. Materials like slag, fly ash, and calcium sulfate are utilized in construction and manufacturing industries, reducing waste and environmental impact. Residual heat is repurposed for heating and fermentation energy. Treated wastewater from mining operations serves as cooling water or process water, conserving resources and preventing pollution. This approach addresses resource scarcity, minimizes waste, mitigates environmental damage, and enhances resource efficiency, contributing to sustainable economic development. Mining tailings, particularly from granite or limestone extraction, can be processed into aggregates for building roads, bridges, and housing. When managed appropriately, these materials reduce dependency on virgin resources like river sand, which are being overexploited. The abandoned tin mine tailings could be repurposed for road construction projects, particularly in rural areas where infrastructure remains underdeveloped. This approach creates jobs whilst addressing Nigeria’s critical infrastructure deficit. Repurposing mining tailings for construction offers economic and environmental benefits, but it also raises health and safety concerns due to residual toxins like silica dust, heavy metals, and radioactive elements. Inhalation of crystalline silica can cause lung diseases such as silicosis, while exposure to heavy metals like lead and arsenic poses serious health risks. Therefore, rigorous safety standards must be enforced to ensure safety in repurposing the waste, including; Comprehensive Material Testing: Ensuring tailings are free from hazardous levels of toxins before use. Proper Processing Techniques: Using encapsulation, stabilization, and chemical treatment to neutralize harmful substances. Workplace Safety Measures: Implementing dust control systems, protective gear, and regular health monitoring for workers. Regulatory Compliance: Establishing strict national guidelines aligned with global best practices (e.g., WHO, EPA) for safe waste utilization Other uses for tailings include; Shotcrete: Tailings can be used to make commercial shotcrete. Concrete: Tailings can be used to make concrete products for mine roads. Insulation: Tailings can be used to make insulation. Foamed products: Tailings can be used to make foamed products Recovering Valuable Minerals from Waste What many fail to realize is that mining waste often contains residual amounts of valuable minerals. Advances in technology now make it economically viable to recover precious metals such as silver, and rare earth elements (REEs) from tailings. In China, rare earth elements are extracted from mine tailings and used in electronics, renewable energy technologies, and electric vehicle components. Nigeria, with its untapped lithium and other critical minerals, could adopt similar practices to supply materials needed for the global energy transition. Reusing Mine Water for Agriculture Mine water can come from two primary sources: groundwater seepage into mine excavations or wastewater generated from ore processing. Often, this water becomes contaminated with chemicals, making it

Harnessing Anaerobic Digestion For Biogas Production In Nigeria

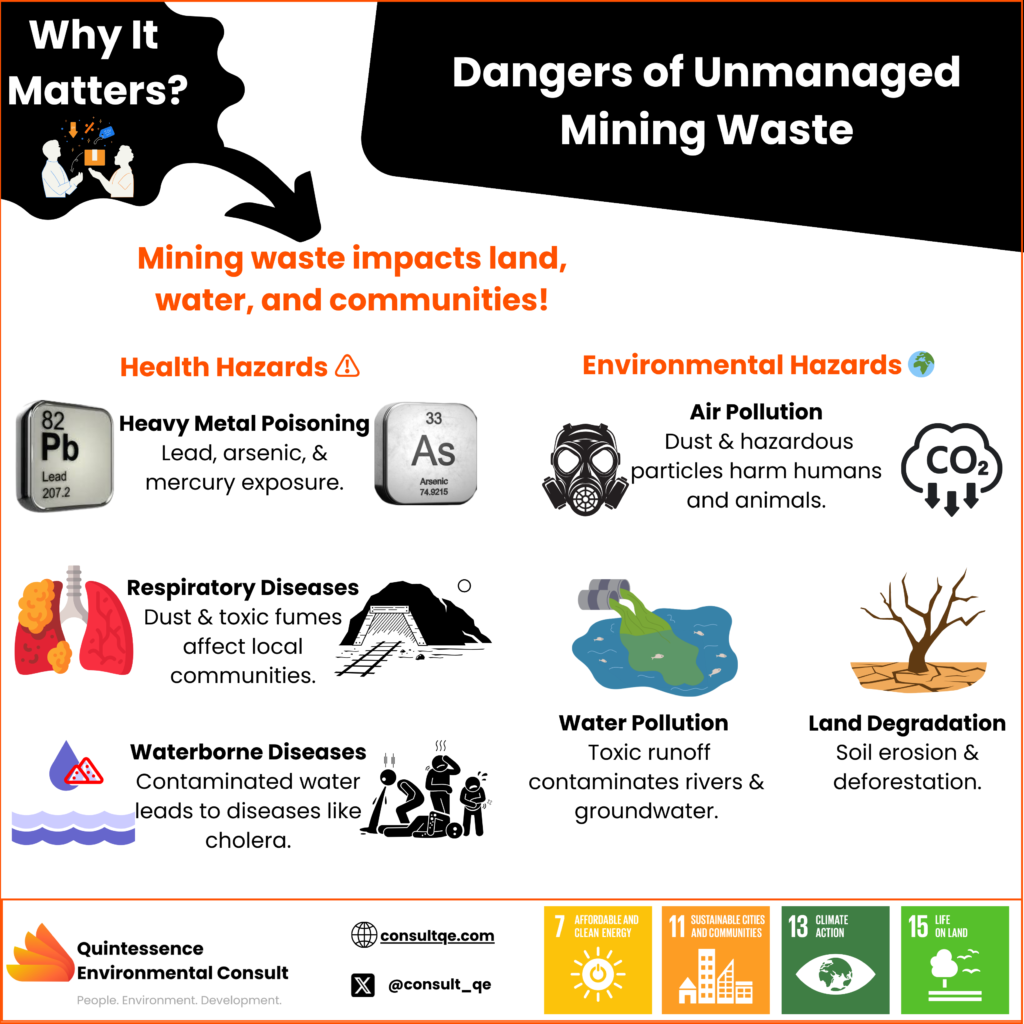

KEY TAKEAWAYS: Nigeria’s reliance on fossil fuel generated GHG emissionsof 100.389MT CO2 in the year 2022, ranking Nigeria to be 4th largest emitter of carbon in Africa. Anaerobic digesters are a great innovation for the country’s renewable energy options. Nigeria has abundant sources of organic waste suitable for biogas production. For instance cattle waste alone has the potential of yielding about 25.53 billion cubic meters of biogas about 169 541.66 MWh of electricity and 88.19 million tons of bio-fertilizer per annum. Biogas production offers diverse advantages, including reducing greenhouse gas emissions, providing clean cooking energy, improving agricultural productivity through digestate use, and supporting off-grid energy access for rural communities. Various projects, such as the biogas plants in Ikorodu-Lagos State, Ibadan-Oyo State, and Usman Danfodiyo University-Sokoto State, demonstrate the feasibility of biogas technology. Biogas production in Nigeria faces barriers like high capital costs, policy and regulatory gaps, lack of infrastructure, limited public awareness, and challenges with feedstock collection and processing. 2. OVERVIEW Nigeria is heavily reliant on fossil fuels, primarily oil, because it is one of the largest oil producers in Africa, with proven reserves of 37.50 billion barrels and a production capacity of approximately 2.19 million barrels per day (mbpd).13 Majority of its government revenue and export earnings come directly from crude oil sales, making its economy heavily dependent on this resource. Heavy dependence on fossil fuels due to its economic value creates significant environmental concerns. Fossil fuels account for more than 65% of the country’s greenhouse gas emissions, with an alarming GHG emissions of 100.389MT CO2 in the year 2022, ranking Nigeria to be 4th largest emitter of carbon in africa.10 As Nigeria takes strides toward achieving its climate and energy transition goals under the Paris Agreement, reducing this dependency will be critical for sustainability and energy security. Biogas produced from the anaerobic digestion of organic matter offers a plethora of benefits for Nigeria’s energy mix; due to its renewable and clean energy resource. In this report, we will explore the transformative potential of harnessing this technology to play a pivotal role in waste management and renewable energy production, offering a sustainable solution to environmental issues in Nigeria. SO, WHAT IS ANAEROBIC DIGESTION? Let’s first talk about Organic Matter. Organic matter comprisesorganic compounds resulting from the remains of decomposed previously living organisms such as plants and animals, and their waste products. Major sources of organic material for anaerobic digestion include dairy manure, food processing waste, plant residues, municipal wastewater, food waste, fats, oils, and grease. Anaerobic digestion (AD) is a biotechnological process that uses the diverse population of microorganisms to decompose organic matter in the absence of oxygen, resulting in the production of biogas—a renewable energy source primarily composed of methane (CH₄). The biotechnological process involves four stages: Hydrolysis, acidogenesis, Acetogenesis and Methanogenesis.10 The transformation of organic matter into biogas unveils anaerobic digesters as an environmentally sustainable and eco-friendly energy solution. BACKGROUND INFORMATION Nigeria’s commitments under the Paris Agreement include achieving NetZero by 2060 and transitioning to clean energy sources.15 As such, Nigeria pledged in its Nationally Determined Contribution (NDC) to adopt bioenergy as an alternative clean energy fuel to enhance its Energy Transition agenda. This supports Nigeria’s Long-Term Strategy for decarbonization, aiming to reduce emissions by 20% below the projected baseline levels by 2030, with a conditional target of achieving a 47% reduction within the same timeframe.16 As Nigeria takes firm strides towards a greener and more sustainable future, biogas emerges as a reliable clean energy technology to facilitate Nigeria’s NDC commitment. CURRENT STATUS OF BIOGAS PRODUCTION IN NIGERIA Although biogas plants are not yet familiar in the Nigerian energy market, some substantial work has been done and work is still in progress on it. For instance: The Usman Danfodiyo University, Sokoto, has designed a plant that can produce 425 litres of biogas per day, sufficient for basic cooking needs. Biogas Plant for electricity generation through gas produced from co-digestion of cassava peels and cow dung at a factory in Ibadan, Oyo State In 2019, the biogas plant at Ikorodu Mini Abattoir, in Lagos State, was capable of converting organic waste through the installation of four 5,000-litre digester tanks, fed with digestible organic waste and concentrated wastewater from the abattoir. Biogas generated was used to power the abattoir for close to six hours daily. The project was carried out by the Lagos State government, Friends of the Environment (FOTE) and HIS Biogas.3 BTNL Nigeria’s project at the Maximum Security Custodial Centre in Port Harcourt focuses on producing organic fertilizer from waste. This initiative aims to convert waste generated within the facility into valuable organic fertilizer, promoting sustainable waste management and supporting agricultural productivity.8 In addition, various research works on the science and technology of biogas production have been carried out by various scientists in the country. The Biogas Practitioners Association of Nigeria (BPAN) and Nigeria Biogas Association (NBA) have attested that despite biogas technology has proven to be a reliable and sustainable source of clean energy that could enable an affordable, reliable and available alternative clean energy solution in Nigeria it has only gained little legislative adoption and implementation in the Nigerian energy policy. 13 SIGNIFICANCE OF BIOGAS PRODUCTION Biogas production offers multifaceted benefits that address energy, environmental, and socio-economic challenges. It’s also suitable for all the various fuel requirements in the household, agriculture and industrial sectors. For instance, domestically, it can be used for cooking, lighting, water heating, running refrigerators, water pumps and electric generators. Agriculturally, it can be used on farms for drying crops, pumping water for irrigation and other purposes. In industries, it can be used in small-scale industrial operations for direct heating applications such as in scalding tanks. 2 Biogas production offers multiple benefits: Providing a sustainable alternative to fossil fuels, contributing to energy security and reducing reliance on non-renewable resources. Biogas systems capture methane emissions from decomposing organic waste that would otherwise escape into the atmosphere, reducing the overall greenhouse gas (GHG) impact, and significantly contributing to climate change mitigation. Anaerobic digestion

Mining without Poison: Addressing the Threat of Heavy Metals in Mining

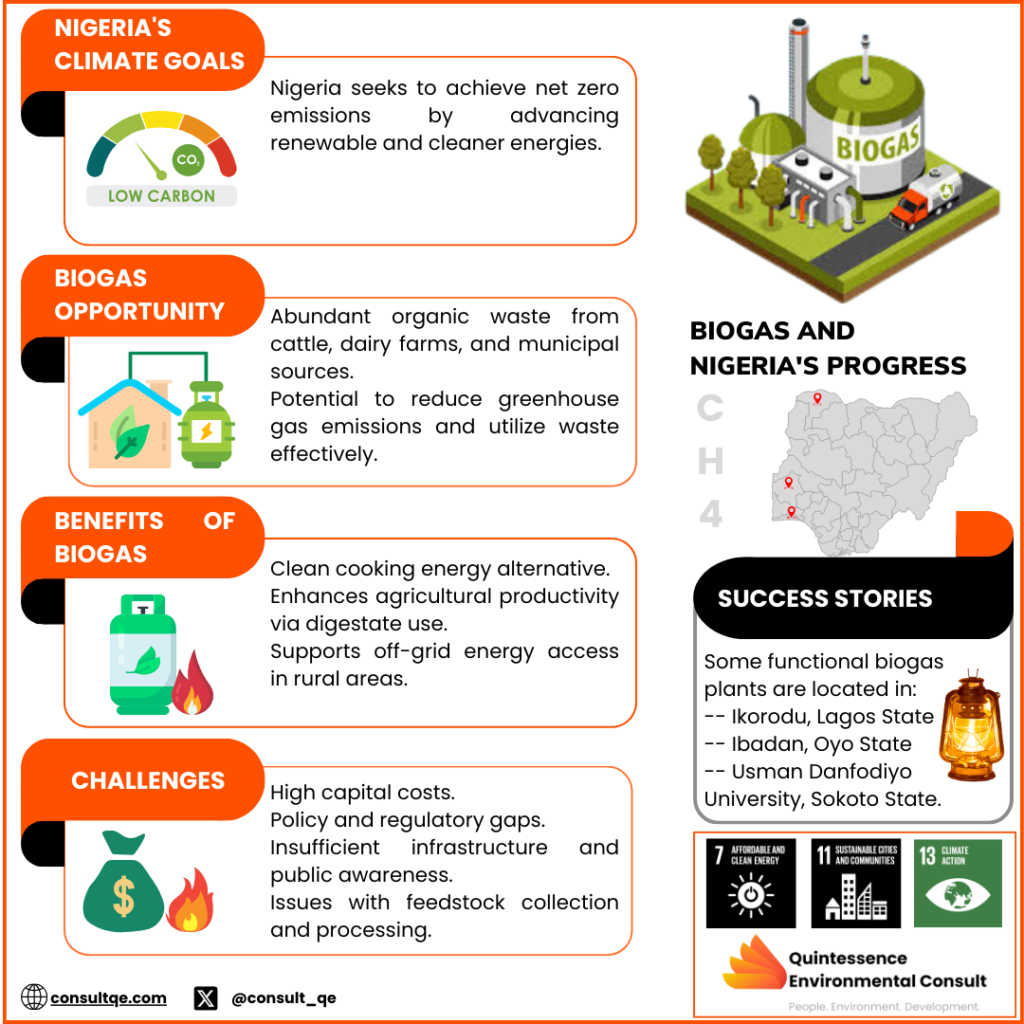

KEY TAKEAWAYS Mining activities release toxic heavy metals such as lead, mercury, and cadmium, posing significant threats to water, soil, air, and human health. Incidents like the 2010 Zamfara lead poisoning epidemic underscore the devastating consequences of unregulated practices. Communities are affected through runoff from mining, which contaminates water sources and impacts drinking water, farming, and aquatic life. Heavy metals reduce soil fertility, disrupt agriculture, and threaten food security. Dust from mining activities contains toxic particles that harm respiratory health, especially among vulnerable populations. Sustainable mining solutions, such as training programs, waste recycling (of mining byproducts), regulation enforcement, and the adoption of mercury-free technologies, should be implemented to reduce pollution risks. The Nigeria-France MoU on critical minerals supports the green energy transition. It emphasizes the importance of sustainable practices in mining to mitigate negative impacts while benefiting from international partnerships. Sustainable mining is crucial for balancing economic opportunities with environmental and societal needs. By adopting safer practices, Nigeria can ensure that its mineral wealth contributes to long-term prosperity without compromising ecosystems or public health. INTRODUCTION Mining activities in Nigeria date back to prehistoric times, with early humans extracting iron, clay, and other minerals for crafting tools, cosmetics, and utensils. The industry was formalized in 1903 when the British colonial administration initiated systematic mineral surveys across the Northern and Southern Protectorates. Over the years, mining has become a pivotal economic driver, fostering industrial growth and providing employment opportunities in communities rich in mineral resources. However, beneath the allure of minerals lies an often-overlooked risk: the threat of heavy metals to life. Mining for resources such as gold, lead, and tin releases heavy metals like mercury, cadmium, and arsenic, which can persist in the environment for decades. These pollutants infiltrate water bodies, degrade agricultural land, and pose severe health risks, including neurological and respiratory issues. To address these hazards, the incorporation of sustainable mining practices is essential. DANGERS OF HEAVY METALS IN MINING Firstly, let us look at what these Heavy metals are. Heavy metals are metallic elements that are toxic or poisonous at low concentrations and have a relatively high density. While naturally occurring, they become hazardous when concentrated or exposed to mining processes. Metals like Lead, Cadmium, and Mercury can seep into waterways, be inhaled as dust, or even accumulate in soils, poisoning plants and animals in the process. When the presence of these toxic nuclides in the environment is enhanced, they will find their way into the human system either by ingestion, inhalation or dermal contact leading to severe health effects like cancer, and damaging important body organs leading to death in some cases 1. Tailings from the gold and beryllium mining activities are often dumped in the immediate environment in tons. This dumping of tailings usually contains higher concentrations of these poisonous elements which is allegedly the leading cause of human exposure that could bring about severe human health effects like arsenicosis, cancer etc., damaging important body organs that could lead to death in some cases 2. Heavy metals are an ongoing concern, particularly in communities surrounding mining sites such as Enyigba (Abakaliki, Ebonyi state), Maru (Zamfara state), Rimin Zayan (Toro, Bauchi state), Tsofo (Birnin Gwari, Kaduna state) and so on. In Osun State, Nigeria, Ilesha and its surrounding areas, including Epe, Igun, and Ijana, are major centers for gold mining due to abundant deposits. However, illegal mining operations have surged, potentially resulting in the contamination of waterways and nearby soils with heavy metals. Studies have indicated that these mining sites are often located near farmlands, where chemicals from the soil may accumulate in arable and cash crops, ultimately leading to severe heavy metal contamination of water sources and posing risks of poisoning to humans and animals if ingested 3. A tragic case unfolded in areas of Maru, Bukkuyum, and Maru in Zamfara State, where artisanal gold mining exposed people to Lead dust, resulting in a devastating Lead poisoning epidemic in 2010. Over 400 children died, and many more suffered long-term health effects due to exposure 4. This heartbreaking example illustrates the dire consequences of unsustainable mining practices and serves as a wake-up call. HOW HEAVY METALS POLLUTE THE ENVIRONMENT AND HARM COMMUNITIES As we already mentioned, mining activities can release heavy metals into the environment in various ways including: Water Pollution: Heavy metals often wash away via runoff from mining sites into rivers, lakes, and underground water sources. This contamination affects drinking water and water used for farming, fishing, and livestock. For example, water bodies in areas with Lead-zinc mining activities, such as Enyigba in Ebonyi State, have shown elevated levels of Lead 5, which could have detrimental impacts on nearby communities who rely on these sources. Soil Contamination: Metals like Cadmium and Lead can accumulate in the soil, rendering farmland infertile or causing toxic crops to grow. In mining-intensive areas, farmers are often forced to abandon affected lands or switch to less nutritious crops, disrupting food security and local economies. Airborne Toxic Dust: Dust particles from mining activities can contain harmful aerosols and heavy metals, which are easily inhaled by residents near mining sites. Children are particularly vulnerable to this exposure. Heavy metal dust from mining areas, such as those in Jos, Plateau State, has posed risks to local communities, showing elevated levels of metals that are known to cause severe health issues 6. MOVING TOWARD SAFER MINING PRACTICE a. Promoting and Supporting Artisanal Mining Training Programs Artisanal miners, who make up a large portion of Nigeria’s mining workforce, often lack training in safe mining practices, thereby exposing themselves and the environment to risks of contamination. Programs that teach miners safer methods, including using less harmful chemicals and protective gear, can dramatically reduce risks. The Nigerian Ministry of Mines and Steel Development has conducted such safety awareness programs in various mining communities, helping to reduce hazardous practices and promote safer alternatives 7. However, more needs to be done to reach a greater number of artisanal miners in the country. b. Recycling Mining Waste In mining, waste is

Health And Environmental Challenges Associated with Plastic Waste

KEY TAKEAWAYS: Plastics are non-biodegradable and may progressively break down into smaller particles (micro and nano plastics) that can be trapped in water and foods without visible traces. Plastics can persist in the environment for 1000 years with only 15% of discarded plastics being recycled globally, highlighting inefficiencies in waste management. Nigeria generates over 2.5 million tonnes of plastic waste annually, and Lagos alone accounts for over 34% (870,000 tonnes) of this. Given the significant threat posed by plastic waste, the Lagos State Government has been most aggressive in managing plastic waste and plans to enforce a ban on specific single-use plastics (SUPs) by January 2025. Most plastic waste eventually ends up in the ocean posing a threat to marine ecosystems. It is estimated that by 2035, plastic waste in the ocean could equal or surpass the total biomass of fish. Plastics contribute to global warming by releasing methane when disintegrating under heat and sunlight and reducing the ability of phytoplanktons to absorb CO₂ and produce oxygen. Methane is more than 25-28 times a more potent greenhouse gas than CO₂. Plastics have both physical and toxic impacts on animals within the ecosystem. Depending on the size and shape of the plastic, the physical impact may include Suffocation, trapping, entanglement, and ulceration of the gut of ingesting animals, etc. Toxic impacts include endocrine disruption, reproductive issues, carcinogenic effects, etc. Toxic impacts of plastics result from pollutants adsorbed on plastic particles, monomers of plastic polymers, and nano-plastics. INTRODUCTION Plastic, a versatile material with numerous applications, has become deeply linked to the comforts of modern life. Since the creation of nitrocellulose, the first semi-synthetic plastic, in 1862 (9), a variety of plastics with expanding properties and uses have been developed. Compared to traditional materials such as glass, wood, and metal, the appeal of plastic lies in its unique characteristics: it is relatively inexpensive to produce, lightweight, tough, stiff, easily fabricated, and offers good insulation for electricity and heat. These attributes have led to its widespread use in sectors like agriculture, construction, transportation, heat insulation, packaging, manufacturing, electronics, furniture, toys, automobiles, and medicine. From 2000 to 2019, rapid population growth and economic advancements have driven global plastic production to nearly double, increasing from 234 million tons to 460 million tons (18). Approximately two-thirds of plastic production consists of single-use plastics, which typically have a lifespan of less than a month. This growing prevalence of plastic waste is a significant concern, particularly in the absence of targeted strategies to address and reduce the issue. Approximately 20 to million metric tons of plastic waste are estimated to enter the environment annually, with projections indicating a substantial rise by 2040 (8). Nigeria is estimated to produce approximately 2.5 million tonnes of plastic waste each year, with Lagos, its commercial hub, contributing 870,000 tonnes (over 34%) annually. Alarmingly, only about 15% of discarded plastics are recycled, leaving vast quantities to accumulate in landfills and ecosystems causing various health, ecological, and climate crises (4). THE PLASTIC WASTE CRISIS Despite its many advantages, synthetic plastics face a significant drawback: they are non-biodegradable due to their structure (long polymer chains) and the presence of additives such as antioxidants. For this reason, discarded plastics may remain in the environment for 1000 years (21). The ocean is the ultimate destination for most plastic waste, which threatens marine biodiversity and ecological balance. By 2035 the amount of plastic waste in the ocean is projected to be equal to or surpass the total biomass of fish, highlighting a severe environmental crisis (20). When exposed to ultraviolet radiation, plastics undergo photo-oxidation, making them brittle and causing them to break into smaller pieces typically classified as macroplastics (>5 mm) and microplastics <1mm). These small plastic pieces are particularly more difficult to manage and pose significant health and ecological threats to aquatic and terrestrial animals. In 2019, microplastics of <0.5mm accounted for 88% of global plastic pollution, contributing to the contamination of ecosystems worldwide (8). In a study conducted recently in Osun River, Nigeria, 22,079 plastic microparticles in 1 liter of water were reported making it the highest reported for any river globally. In the same study, between 407 to 1691.7 microplastic particles were found in the gastrointestinal tract (GIT) of six fish species analyzed. Microplastic has also been recovered in several other rivers in Nigeria including Nwangele River in Imo State, Kaduna River, and Elechi Creek, in Port Harcourt. ADVERSE EFFECTS OF PLASTIC WASTE ON THE ECOLOGY, HUMAN HEALTH, AND GLOBAL CLIMATE Ecological impact of plastic waste Plastics disrupt aquatic ecosystems in multiple ways, every organism in an ecosystem has a distinct and essential role contributing to the overall ecological balance and functions. Plastic has various adverse effects on different classes of aquatic animals in the ecosystem. These effects may have physical or toxic impacts Physical Impact: Plastic particles of varying shapes and sizes physically harm small and large aquatic animals including such as seabirds, turtles, fish, crustaceans, etc. These harms are typically caused by suffocation, entrapment, entanglement, and ingestion of plastic particles (5). Entrapped or entangled animals may lose their ability to hunt, evade prey, or drown. Ingested plastics may block digestive tracts, damage stomach linings and give a false sense of satiation to the animals. Toxic Impact: Plastics have direct and indirect toxic impacts on aquatic life plants and animals. Direct impacts include toxic impacts from nanoplastic particles as well as monomers and hazardous additives like plasticizers and flame retardants leaching from the plastic polymers. Indirect toxic impact results when plastic serves as a vector for other organic pollutants, heavy metals, and pathogens attached to plastics. In animals, toxic impacts include early mortality, inflammatory responses, inhibited growth and development, reduced energy, low feeding activity, oxidative damage, immunity and neurotransmission dysfunction, and even behavioral abnormality, etc. Plastic particulates can cause unfavorable changes to plant growth, germination, and oxidative stress in plants (7). Studies have shown microplastics in rivers and aquatic animals. This poses significant health to humans that rely on such rivers for cooking and drinking especially in where municipal water treatment plants have not been updated to remove microplastic. Similarly, plastic

Emerging Trends and Opportunities in Plastic Waste Recycling in Nigeria

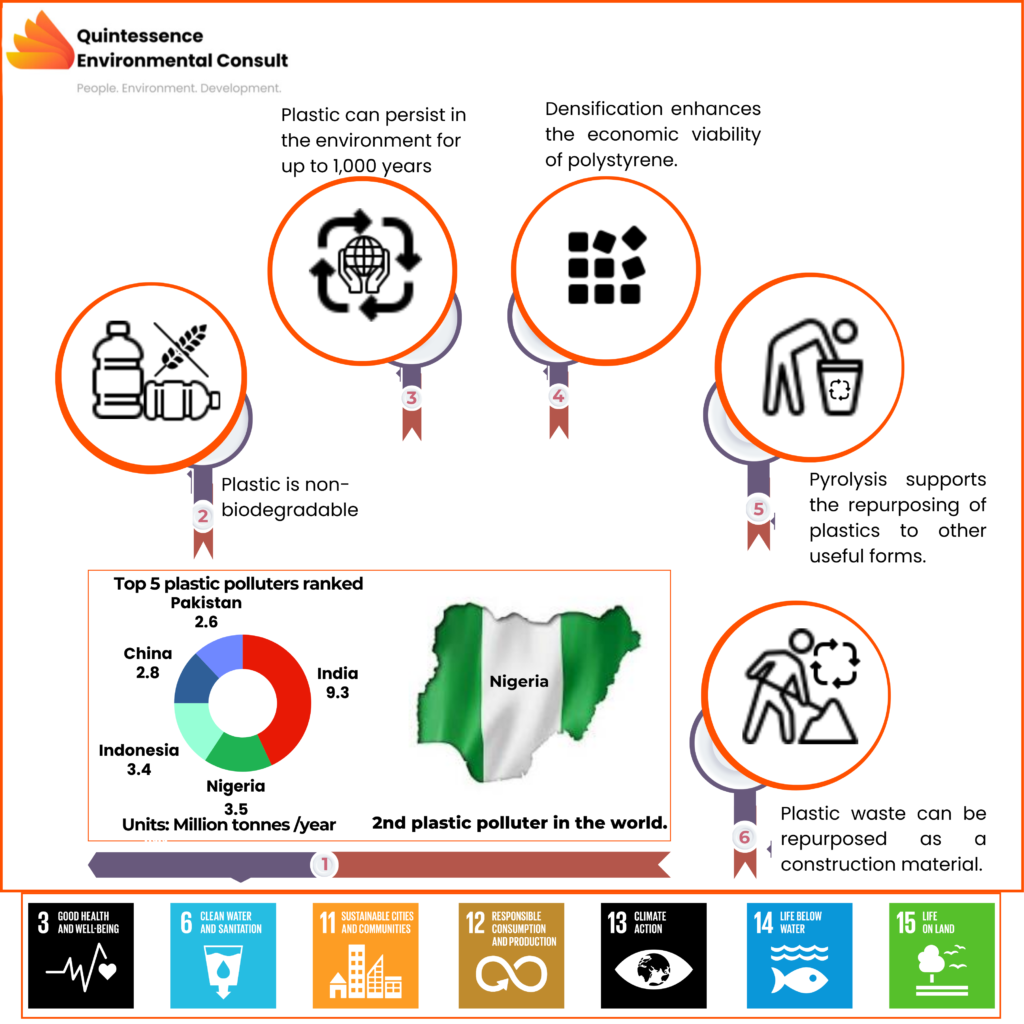

The Foundation for Investigative Journalism reports that Nigeria is now the second largest plastic polluter in the world only behind India. TAKEAWAYS Innovative Recycling Techniques: Densification: Enhancing the economic viability of polystyrene by compressing it into blocks, easing transportation costs and making recycling more profitable Plastic pellets and flakes: Polyethylene terephthalate (PET) bottles are collected, sorted, washed and processed into pellets and flakes and sold to advanced recycling companies Pyrolysis: A waste to chemical technology that converts plastics into pyrolysis oil which may be processed into new plastic or other chemical. A pilot pyrolysis unit by BASF Nigeria is being proposed for Lagos. Plastics in Construction: Innovative use of plastic waste as building materials is gaining traction. Examples include PET bottles filled with sand to construct buildings and plastic sand composites for bricks and tiles for pavements. A UNEP Intergovernmental Negotiating Committee (INC) on plastic pollution is developing a legally binding international instrument to advance the management of plastic pollution. For Nigeria to remain competitive in plastic management it must take advantage of available financial technological instruments. The UNEP Finance Leadership Group on Plastics, a core group of banks and insurers is charged with developing financing framework for plastic pollution. BACKGROUND Global plastic production is estimated at over 460 million tons annually, much of which are discarded as waste after use. Plastic is a non-biodegradable material and can persist in the environment for 100 to 1,000 years, constituting significant health and environmental challenges. It is estimated that Nigeria generates 3.5 tons of plastic waste annually making it 2nd globally after India. The world is plagued with excessive plastic waste and Nigeria is no exception. As plastic waste clog water drainages, it has been identified as one of the factors contributing to the severity of flooding in Nigeria. In spite of the technological limitation of plastic waste management in Nigeria, there are interesting innovative and home-grown ideas that deserve acknowledgment, support and promotion in order to ameliorate the disastrous effect of plastic. Meanwhile, plastics come in different compositions and are not all equal. The most common plastics in use are: Polypropylene (PP), Polyethylene Terephthalate (PETE or PET), Polyvinyl Chloride (PVC) and Acrylonitrile-Butadiene-Styrene (ABS). PROCESSING PLASTIC WASTE FOR EXPORT PET bottles are the most sought-after type of plastic by recycling companies. The demand for recycled polyethylene terephthalate (rPET) is increasing due to regulations aimed at reducing virgin plastic production and encouraging Extended Producer Responsibility (EPR). The global market for recycled PET is estimated to exceed $5 billion, presenting investment opportunities for recycling companies in Nigeria. Local companies like Labacorp Energy, Alef Recycling, and others collect, sort, wash, and process PET bottles into flakes and pellets for export. DENSIFICATION OF PLASTIC TO ENHANCE ECONOMIC VALUE Although polystyrene can also be recycled, its high processing costs make it less appealing to local recyclers in Nigeria. However, densification can enhance its economic viability by making transportation cheaper and easier. Wecyclers Corporation is partnering with BASF Nigeria to densify polystyrene waste into compact blocks with a density of 950-1050 kg/m³, which will reduce shipping costs to larger recycling firms abroad. PLASTIC AS A BUILDING AND FASHION MATERIAL Plastics can be utilized in various construction applications. For example, PET (Polyethylene terephthalate) bottles filled with dry sand, wet sand, or air and reinforced with cement can act as building blocks. In 2011, the Development Association for Renewable Energies built Africa’s first prototype house using sand-filled PET bottles in Yelwa, Kaduna State, Nigeria. This structure is about 18 times stronger and twice as cost-effective as conventional blocks, providing excellent insulation with a consistent temperature of 18°C. Figure 1. Social Innovation Academy (SINA) Project (Source: https://www.greiner.com/en/blog/detail/houses-made-from-plastic-bottles-yes-that-exists/) Another innovative material is plastic sand composite, created by heating a mixture of plastic and sand, where the plastic serves as a binder. This composite can be used to produce bricks, manhole covers, and more. In Kenya, Gjenge Makers LTD and in Ghana, Nelplast Eco Ghana LTD are successful startups using extrusion machines to manufacture plastic sand composites for building materials and paving tiles. While it’s uncertain if similar machines exist in Nigeria, some startups are reportedly using basic methods to heat mixtures of plastic and sand to make bricks and tiles. A notable example is Ifrique Eco Solutions, founded by Instissar Bashir Kurfi, which produces composites from nylon plastic using open-air heating. Additionally, nylon can be repurposed for fashion items. Planet 3R, founded by Adegoke Lasisi, creates beautiful products like bags, shoes, and purses from water sachets and other nylon and textile waste. Figure 2. Eco-Tiles for Pavements (Source: ifrique.com) Figure 3. Laptop Bag (Source: https://www.planet3r.com/project/laptop-bag/) PLASTIC WASTE-2-CHEMICAL USING PYROLYSIS Pyrolysis is a thermochemical recycling technology that breaks down plastic into its monomeric units. The product of this process is known as pyrolysis oil. The oil may serve as fuel or secondary raw material for the production of other plastic products. Unlike other recycling processes, pyrolysis does not require sorting and plastic produced from pyrolysis oil is of higher quality compared to products from tradition recycling technology. However, this technology is beyond the reach of local plastic recycling companies in Nigeria. In 2023, BASF Nigeria proposed establishing the country’s first pyrolysis unit in Lagos. If successful, this pilot project could be expanded nationwide. The oil produced from this process could generate enough energy to operate the unit, with excess oil collected and shipped to centralized locations for export as secondary raw materials for various products. OTHER OPPORTUNITIES AND THE FUTURE OF PLASTIC WASTE MANAGEMENT Virgin plastic is less expensive than recycled plastic, making it crucial for policies to encourage plastic recycling while discouraging the use of virgin plastic. This goal aligns with the core mission of the UNEP Intergovernmental Negotiating Committee (INC) on plastic waste, which is developing a legally binding international framework for managing plastic waste. The ability of governments worldwide to implement this framework after ratification will largely depend on the technological advancements of each member state. Thus, it is vital to understand Nigeria’s current position in the waste management value chain. Nigeria must ensure it does not hinder the regional progress toward a fully circular economy in the plastic sector. To