KEY TAKEAWAYS

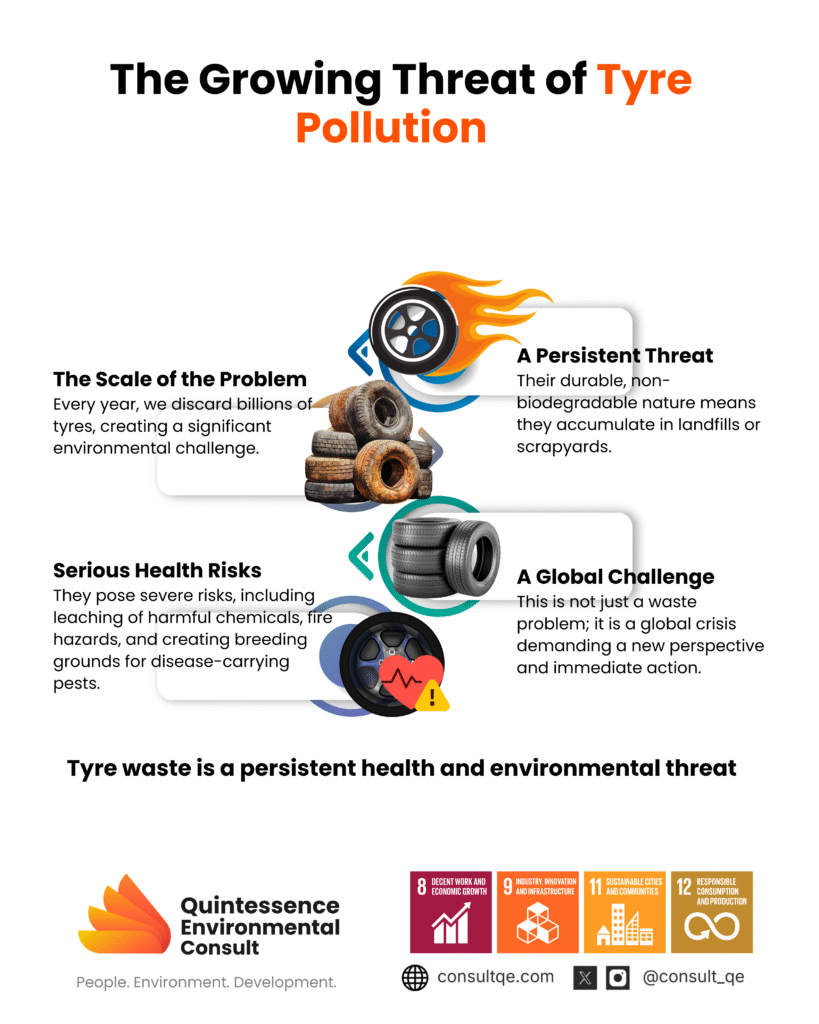

- Instead of being stockpiled, burned, or landfilled, end-of-life tyres are now repurposed into higher-value products such as rubberized asphalt, flooring, playground surfaces, and even energy sources.

- Global momentum is building from Europe’s 97% recycling rate to the U.S. reducing tyre stockpiles by 95%, and Asia-Pacific’s rapid growth led by Japan, India, and China, regions across the world are embedding tyre upcycling into circular economy strategies.

- Upcycling supports infrastructure resilience, energy efficiency, and environmental conservation while cutting greenhouse gas emissions and reducing reliance on virgin raw materials like crude oil and natural rubber.

- Technical barriers, high investment costs, market hesitancy, regulatory gaps, and environmental concerns, such as microplastic release, continue to limit the sector’s potential.

- Overcoming these challenges requires innovation in technology, strong regulatory frameworks, financial incentives, and education campaigns to drive consumer and industry trust in upcycled tyre products.

INTRODUCTION

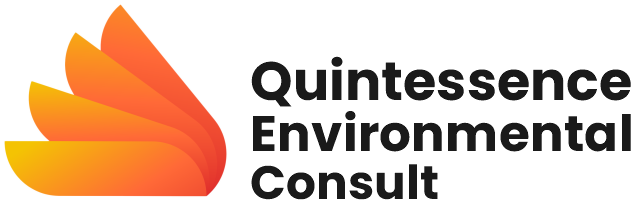

Every year, billions of tyres are manufactured, serving a vital role in transportation across the globe. However, once these tyres reach the end of their life, they pose a significant environmental challenge. Their durability and non-biodegradable nature cause them to accumulate in landfills or scrapyards, contributing to pollution through leaching of harmful chemicals, fire hazards, and the creation of breeding grounds for disease-carrying pests.

Tyres are highly engineered composites made from a blend of materials designed to ensure strength, flexibility, and durability. On average, they consist of 10–40% natural rubber for elasticity, 20–60% synthetic rubber (such as styrene-butadiene and butadiene rubber) for abrasion resistance, 15–30% carbon black or silica as reinforcing fillers, 10–15% steel for structural support in belts and beads, and 3–8% textile fibres such as nylon, polyester, or rayon for stability. In addition, 5–10% chemical additives (including sulphur for vulcanization, oils, antioxidants, and resins) are incorporated to enhance resistance to heat, oxidation, and UV degradation. These components work together to create tyres that can withstand heavy loads, high temperatures, and constant friction, making them critical to modern transport systems. 13, 15

The lifespan of tyres depends on type, usage, and maintenance practices. Passenger car tyres typically last between 40,000 and 80,000 km (3–6 years), while truck tyres often achieve 80,000–120,000 km and can be retreaded up to three times, significantly extending service life. Motorcycle tyres generally endure 20,000–30,000 km, whereas aircraft tyres are designed for extreme stress and can be retreaded multiple times, with some casings lasting up to 500 landings. . 10 Tyres are also evaluated under grading systems such as the Uniform Tyre Quality Grading (UTQG), which measures treadwear (relative durability), traction (rated AA–C for braking on wet surfaces), and temperature resistance (rated A–C). They are further categorized by application (passenger, truck, motorcycle, agricultural, off-road, and aircraft tyres), structure (radial tyres for durability and efficiency; bias-ply tyres for flexibility in heavy-duty uses), and performance (summer, winter, all-season, high-performance, and run-flat tyres). This diversity reflects the balance between safety, environmental performance, and consumer needs in tyre design. 12

WHAT IS TYRE UPCYCLING

Tyre upcycling, also known as advanced tyre recycling, seeks to reimagine end-of-life tyres (ELTs) not as waste but as feedstock for higher-value products and services. Instead of relying on outdated approaches such as landfilling, incineration, or low-grade shredding, tyre upcycling offers innovative pathways that align with the circular economy. 14

GLOBAL IMPLEMENTATION

The concept of tyre recycling and upcycling is gaining traction worldwide as governments and industries implement large-scale initiatives to address the growing problem of End-of-Life Tyres (ELTs). Regions with strong circular-economy policies and public procurement requirements (such as mandating recycled content in public works) achieve broader adoption of upcycled tyre products; In other regions, entrepreneurial SMEs and NGOs drive implementation.

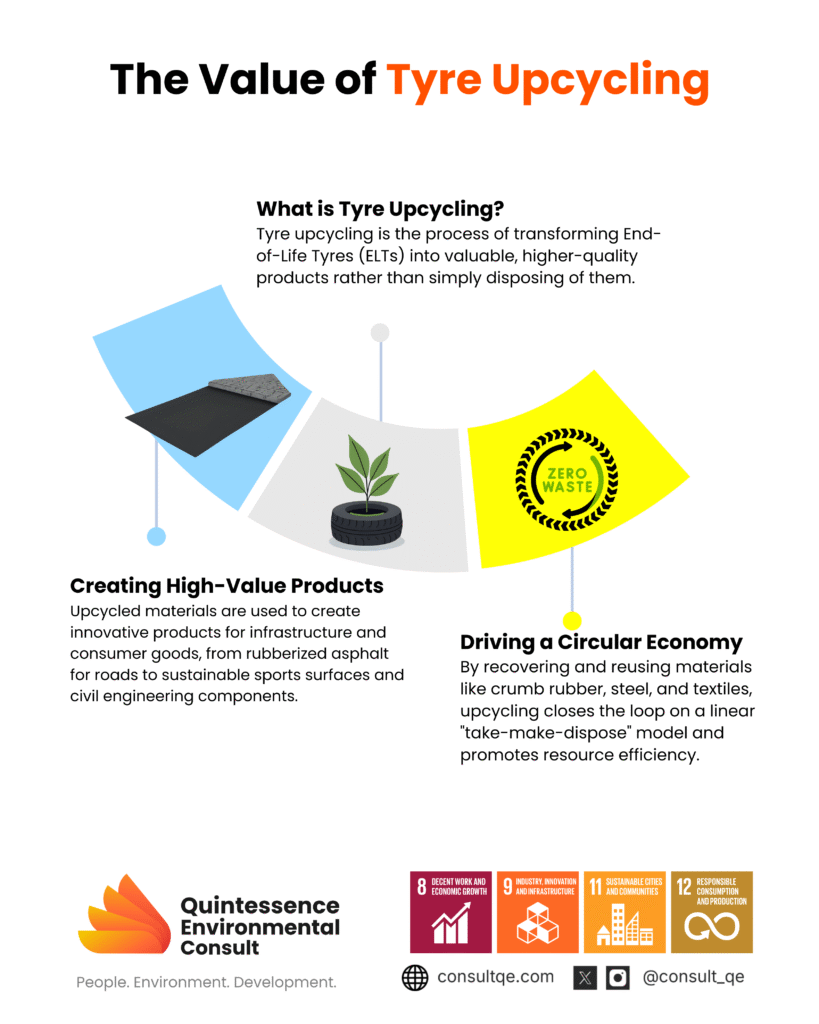

- Europe: Europe stands out globally as a leader in tyre upcycling due to strong regulatory frameworks. On 13 June 2025, the European Tyre and Rubber Manufacturers’ Association (ETRMA) reported that 97% of ELTs in 32 European countries were collected and treated. This success is largely due to Extended Producer Responsibility (EPR) schemes, which make tyre manufacturers legally and financially accountable for end-of-life management of their products.6 Recycled tyre materials are widely used in civil engineering, energy recovery, and sports surfaces. Countries such as Germany and the Netherlands demonstrate particularly high recycling rates, showcasing efficient systems for material separation and processing. 7

- United States Progress and Trends: In the United States (US), tyre recycling has also made significant strides. The country currently processes 317 million end-of-life tyres annually (approximately 4.2 million tonnes), achieving a 79% recycling rate that has improved dramatically from just 11% in 1990. This progress has been accompanied by significant reductions in tyre stockpiles, from more than 1 billion tyres in 1990 to only 48 million in 2024, representing a 95% reduction through systematic clean-up and prevention programmes.⁴ Most recycled tyres in the US are repurposed into tyre-derived fuel (TDF), rubberized asphalt for road construction, and ground rubber for playgrounds. These applications not only reduce waste but also enhance infrastructure resilience and contribute to energy recovery.

- Asia-Pacific: The Asia-Pacific region represents the fastest-growing tyre recycling market globally, driven by rapid industrialization and increasing environmental awareness. Japan has emerged as a leader in adopting advanced recycling technologies, achieving a 92% recycling rate while processing 85 million tyres annually (980,000 tonnes). China processes over 180 million tyres annually (2.1 million tonnes), while India generates 112 million waste tyres annually and has set a target to recycle 75% by 2025. China and India are rapidly improving their infrastructure and investment in recycling industries. 4

- Africa’s Emerging Opportunities: Africa presents significant untapped potential for tyre upcycling, driven by a rapidly growing automotive industry and the urgent need for sustainable waste management. Initiatives across the continent are transforming this challenge into an opportunity, creating jobs and fostering local industries that utilize recycled tyre products. South Africa processes an estimated 11 million tyres annually, with evolving Extended Producer Responsibility (EPR) frameworks enhancing collection and processing capabilities. Nigeria generates around 25 million waste tyres each year, and emerging formal recycling programmes are beginning to unlock significant development opportunities. 4, 5 One notable example is FREEE Recycle Limited, a Nigerian company founded in 2020. It has recycled more than 350,000 tyres to date, producing tiles, mats, paving bricks, flip-flops, and other rubber goods. The company aims to scale up operations to process 2 million tyres annually, demonstrating the potential of private-sector innovation in Africa’s tyre upcycling landscape. 3

TECHNOLOGICAL FRONTIERS

As the global demand for sustainable waste management grows, several technological frontiers are emerging in tyre upcycling. These innovations aim to maximize material recovery, improve economic viability, and minimize environmental risks.

- Pyrolysis and devulcanization: Pyrolysis and devulcanization represent advanced technological frontiers in tyre upcycling. Pyrolysis thermally decomposes tyres in the absence of oxygen, producing oil, gas, steel, and carbon black, which can be reintegrated into industrial processes. Devulcanization, on the other hand, breaks sulphur bonds in vulcanized rubber, allowing reclaimed rubber to be used in new tyres or other products. These methods enable a closed-loop system, transforming discarded tyres into high-value products and advancing the principles of a circular economy. Currently, these technologies are scaling up across Europe, North America, and parts of Asia, supported by broader circular economy strategies. 11

- Rethreading and Reuse: Retreading and direct reuse extend the lifespan of waste tyres and reduce environmental pressures. Retreading, primarily applied to truck and aircraft tyres, involves replacing worn treads, requiring only about 30% of the energy and 25% of the raw materials needed to produce a new tyre. According to Gutowski et al. (2011), Studies have shown that retreading a heavy-duty truck tyre can save up to 68% of energy during production, although benefits may decline depending on reduced durability and increased rolling resistance. Although retreading is in line with the circular economy and aims to expand the lifetime of products, it is currently only an established practice for truck and aircraft tyres, but not for automobile tyres, due to economic profitability. Retreading is typically limited to up to three times. 8

- Crumb Rubber Technology: Shredding tyres into fine crumb rubber enables their use in road surfacing, sports fields, playgrounds, and moulded products. Rubberized asphalt, for instance, extends pavement life and reduces road noise, while crumb rubber in sports and recreational surfaces offers resilience and durability. Research into encapsulation methods is addressing environmental concerns related to leaching and microplastics release.

- Innovative Community and Creative Uses: Grassroots projects are also pushing the frontier by transforming tyres into furniture, planters, art installations, and modular construction blocks. Across various African nations, these upcycling efforts are increasingly turning discarded tyres into valuable consumer goods like mats, flooring, furniture components, sports surfaces, retaining walls, and modular building blocks. These initiatives promote local employment, community engagement, and circular thinking, particularly in regions with limited formal recycling infrastructure. 4

BENEFITS OF TYRE UPCYCLING

Tyre upcycling goes beyond waste reduction, providing tangible economic, environmental, and social benefits.

- Circular Economy Creation: Upcycling recovers crumb rubber, steel, and textiles, feeding them back into new production systems and closing the loop on a linear “take-make-dispose” model. 1

- Infrastructure Resilience: Tyre-derived aggregates (TDA) can be used in road embankments, slope stabilization, and drainage systems. Rubber additives extend pavement life, while permeable rubber paving supports flood management. 14

- Energy and Resource Efficiency: Producing recycled rubber crumb consumes 70–85% less energy than creating virgin rubber, cutting greenhouse gas emissions substantially. 7

- Economic Growth: Tyre upcycling creates domestic manufacturing opportunities, from rubberized asphalt plants to flooring and sports surfacing factories, generating jobs and new revenue streams. It also creates new revenue streams from the sale of recycled materials, providing cost savings for businesses that use them as a raw material. 1, 2

- Environmental Conservation: Tyre stockpiles are reduced, fire hazards are minimized, and reliance on crude oil for new tyre production is decreased. It reduces the demand for natural resources like rubber trees, preventing deforestation and its climate impact. It reduces the need for tyre incineration, which emits harmful air pollutants; absorbs sounds, reducing noise pollution; prevents open dumps and mininizes the release of toxic chemicals and heavy metals from its landfilling. 5, 9

CHALLENGES

Despite the growing momentum of tyre upcycling, several challenges continue to hinder its full potential. One of the most significant technical barriers lies in the heterogeneous composition of tyres, which contain complex blends of rubber, steel, and textiles. Producing consistent, high-quality upcycled materials requires advanced sorting technologies and standardized processing methods.11

Economic competitiveness remains another obstacle, as setting up recycling facilities requires substantial capital investment. Pyrolysis and devulcanization face significant economic hurdles, as many plants struggle with high capital costs, inconsistent product quality, and limited market demand for recovered outputs. Profitability is often undermined by competition with cheaper virgin materials and fluctuating oil prices, making large-scale adoption difficult. While both technologies are promising, their commercial scalability remains constrained, with most successes seen only in pilot projects or niche markets.

Market acceptance is also a critical factor. Many industries remain hesitant to switch from virgin materials due to concerns over quality and performance. Regulatory and standards gaps pose additional challenges, particularly the lack of uniform global standards for tyre-derived materials.

Environmental and health concerns have also drawn scrutiny, especially regarding chemical leaching, microplastic release, and emissions from thermal processes like pyrolysis. These environmental and health risks undermine public trust and generate resistance from regulators and communities.

Finally, logistics and collection remain major hurdles due to the bulkiness of tyres and the costs of transportation. Limited collection infrastructure, particularly in developing regions, hinders consistent supply, while inadequate systems reduce recovery rates.

RECOMMENDATIONS

To overcome technical barriers, investment in advanced sorting technologies and the development of standardized mechanical and chemical processing methods is essential.

On the economic front, public–private partnerships combined with government incentives such as tax breaks, subsidies, and grants can help bridge financial gaps and improve the competitiveness of tyre upcycling. For pyrolysis and devulcanization specifically, greater research and development investment into cleaner, more efficient systems, coupled with industrial partnerships, can improve consistency, reduce costs, and secure stable demand for recovered outputs. Policies that reward circular economy outcomes, rather than favouring cheap disposal, will also drive long-term sustainability.

To improve market acceptance, standardized performance metrics, third-party certification, and transparent labelling are crucial. Demonstrating successful case studies and launching targeted awareness campaigns can further dispel misconceptions and encourage the adoption of tyre-derived products.

Regulatory frameworks must also be strengthened. Governments and international bodies should establish harmonized standards for tyre-derived materials, alongside clear end-of-life management guidelines and reliable test methods for environmental risks.

Addressing environmental and health concerns requires implementing encapsulation techniques for crumb rubber applications, strict emission control systems for thermal processes, and long-term independent studies to track impacts and build public trust. Finally, logistics can be improved by optimizing collection routes with advanced modelling tools, establishing standardized regional collection systems, expanding consumer collection points, and promoting tyre retreading—particularly in commercial fleets—to extend lifespan and reduce waste generation.

CONCLUSION

Tyre upcycling is more than a waste management strategy; it is a cornerstone of the circular economy. By viewing end-of-life tyres as resources rather than waste, societies can reduce environmental hazards, strengthen supply chains, and unlock economic growth. To fully realize its potential, the sector must overcome technical, economic, and social challenges, and overcoming these challenges requires a holistic approach that combines technological innovation, supportive policy frameworks, financial incentives, and community engagement. By addressing these barriers strategically, tyre upcycling can evolve into a cornerstone of the global circular economy with transforming one of the world’s most persistent waste streams into a driver of sustainable development.

REFERENCES

- Adelagan, J. (2024). Strengthening the circular economy in the international rubber value chain: Perspectives for value addition Joseph Adelegan Secretary-General and Executive Head International Rubber Study Group (IRSG). [online] Available at: https://unctad.org/system/files/non-official-document/joseph-adelegan_myem2024.pdf.

- Afeez Siyanbola (2020). Capacity-Building in Waste Wealth: Reusing of Discarded tyres for Making Home use Furniture. [online] Academia.edu. Available at: https://www.academia.edu/70393775/Capacity_Building_in_Waste_Wealth_

- Reusing_of_Discarded_tyres_for_Making_Home_use_Furniture.

- Ayanfeoluwa, P. (2024) ‘Waste recycling sector potential untapped — FREEE Recycle’, Vanguard, 24 September. Available at: https://www.vanguardngr.com/2024/09/waste-recycling-sector-potential-untapped-freee-recycle/

- Donnelly, K. (2025). tyre Recycling Industry Statistics: Global Market Analysis. [online] Gradeall International LTD. Available at: https://gradeall.com/tyre-recycling-industry-statistics-global-market/

- Edom, S. (2023). How To Start A Tyre Recycling Business in Nigeria & Africa. [online] Africa’s Young Entrepreneurs. Available at: https://ayeorganization.com/2023/08/05/how-to-start-a-tyre-recycling-business-in-nigeria-africa/#:~:text=In%20Nigeria%20and%20Africa%2C%20the,preservation%

- 20and%20circular%20economy%20initiatives.

- ETRMA. (2025). End-of-life tyres in a circular economy: ETRMA’s perspective on a competitive recycling sector – ETRMA. [online] Available at: https://www.etrma.org/news/end-of-life-tyres-in-a-circular-economy-etrmas-perspective-on-a-competitive-recycling-sector/.

- Goevert, D. (2024). The value of different recycling technologies for waste rubber tyres in the circular economy—A review. Frontiers in sustainability, 4. doi:https://doi.org/10.3389/frsus.2023.1282805.

- Goevert, D. (2024) ‘The value of different recycling technologies for waste rubber tyres in the circular economy — A review’, Frontiers in Sustainability, 4, 1282805. doi: 10.3389/frsus.2023.1282805.

- Hashamfirooz, M., Dehghani, M.H., Khanizadeh, M., Aghaei, M., Bashardoost, P., Hassanvand, M.S., Hassanabadi, M. and Momeniha, F. (2025). A systematic review of the environmental and health effects of waste tyres recycling. Heliyon, [online] 11(2), p.e41909. doi:https://doi.org/10.1016/j.heliyon.2025.e41909.

- Huang, J., Li, G., He, W. and Xu, J. (2012) ‘Energy analysis of tire life cycle’, Automotive Engineering, 34(3), pp. 277-281. Available at: https://www.researchgate.net/publication/279908937_Energy_analysis_

- of_tire_life_cycle

- Kumar, D., Pei, Y., Han, B., Khoo, S.Y., Norton, M., Adams, S.D. and Kouzani, A.Z. (2025). Comparative analysis of waste tyre treatment technologies: Environmental and economic perspectives. Renewable and Sustainable Energy Reviews, [online] 216, p.115691. doi:https://doi.org/10.1016/j.rser.2025.115691.

- National Highway Traffic Safety Administration (NHTSA). (2006) The Pneumatic Tire: DOT HS 810 561. Washington, D.C.: U.S. Department of Transportation. Available at: https://d1wqtxts1xzle7.cloudfront.net/36497760/PneumaticTire_HS-810-561.pdf

- Parilov, R.G. (2011) Comprehensive Classification of Tire Types. Siberian Federal University. Available at: https://elib.sfu-kras.ru/bitstream/handle/2311/4637/7001.pdf?sequence=1

- Sathiskumar, C. and Karthikeyan, S. (2019). Recycling of waste tyres and its energy storage application of by-products –a review. Sustainable Materials and Technologies, 22, p.e00125. doi:https://doi.org/10.1016/j.susmat.2019.e00125.

- Sienkiewicz, M., Kucinska-Lipka, J., Janik, H. and Balas, A. (2012) ‘Progress in used tyres management in the European Union: A review’, Waste Management, 32(10), pp. 1742–1751. doi: 10.1016/j.wasman.2012.05.010.