KEY TAKEAWAYS

- Despite growing awareness, the vast majority of plastic produced still ends up in landfills or the environment, with only a small fraction effectively recycled.

- Effective recycling of plastics has a purity issue as contamination of plastic feedstock during sorting drastically reduces the quality of recycled materials, limiting their applicability and subsequent recycling cycles.

- Holy Grail 1.0 & 2.0, these initiatives, particularly HolyGrail 2.0, leverage digital watermarking technology to embed invisible, machine-readable codes on plastic packaging for highly accurate and efficient sorting.

- HolyGrail 2.0 has demonstrated remarkable detection rates (87.9%-93.8%), high sorting purity (95% average), and impressive speed, even under challenging industrial conditions.

- Although an EU initiative, the HolyGrail 2.0 technology holds immense potential for countries like Nigeria, offering a path to improve recycling infrastructure and promote a circular economy.

INTRODUCTION

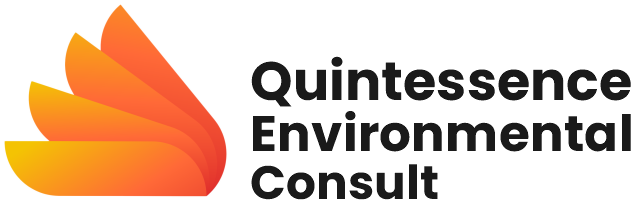

Plastic waste has become an undeniable global crisis, presenting severe environmental and socio-economic challenges. Our modern lives are intricately woven with plastic, making it seemingly impossible to extricate ourselves from its pervasive presence. The production of virgin plastic continues to soar, with estimates suggesting a cumulative volume exceeding 25,000 million metric tons by 2050 if the current 8.4% growth rate persists3.

Alarmingly, of all virgin plastic ever produced, only a minuscule 9% is recycled, while 12% is incinerated. The vast majority, a staggering 79%, accumulates in landfills or pollutes our natural environment3. While recycling is theoretically the most preferred method for plastic waste management, allowing for infinite reprocessing, this remains a distant ideal. Currently, only about 10% of all recycled plastic enters a second recycling cycle3. This stark reality implies a continuous influx of virgin plastic into the market, even with increased recycling efforts. The problem is exacerbated by the prevalence of single-use plastics, which are often discarded within a month or less, contributing significantly to environmental accumulation.

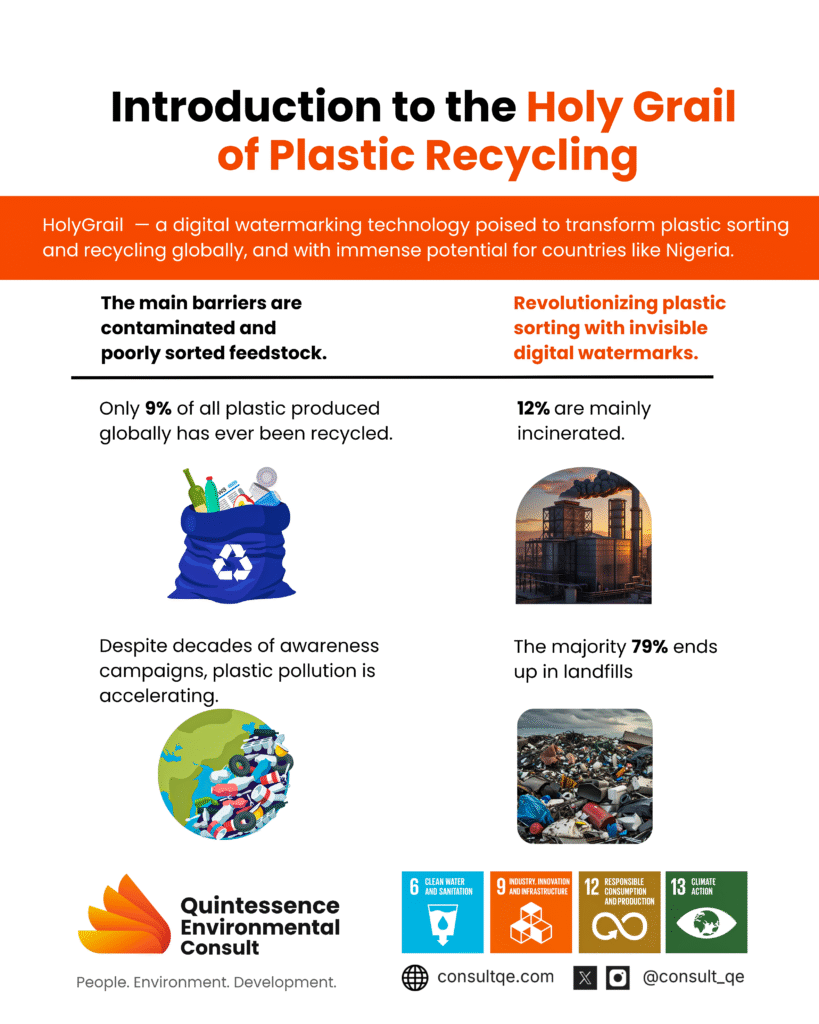

The primary bottleneck in achieving true plastic circularity lies in sorting. The quality of recycled plastic is directly proportional to the purity of its feedstock. When different plastic polymers contaminate the feedstock, the resulting recycled product’s quality diminishes significantly, limiting its potential for subsequent recycling. Such recycled plastics, often blends of polymers, are typically relegated to non-food packaging applications². Therefore, the “holy grail” of plastic recycling isn’t just about collecting plastic, but about adequate and advanced sorting technologies that are fast, resilient, and highly accurate in achieving high polymer purity.

- Near-Infrared (NIR) sorting: Highly efficient but less effective for dark-colored plastics that absorb infrared light.

- Air classification: Separates plastics based on density and aerodynamic properties.

- Electrostatic separation: Utilizes electrostatic charges to differentiate plastics.

- Float-sink (dense medium separation): Separates plastics based on their density relative to a liquid medium.

- Hydrocyclone sorting: Employs centrifugal force to separate particles based on density and size.

Despite these advancements, a universal, highly accurate, and rapid sorting solution remained elusive until now.

HOLY GRAIL 1.0: A GLIMMER OF HOPE

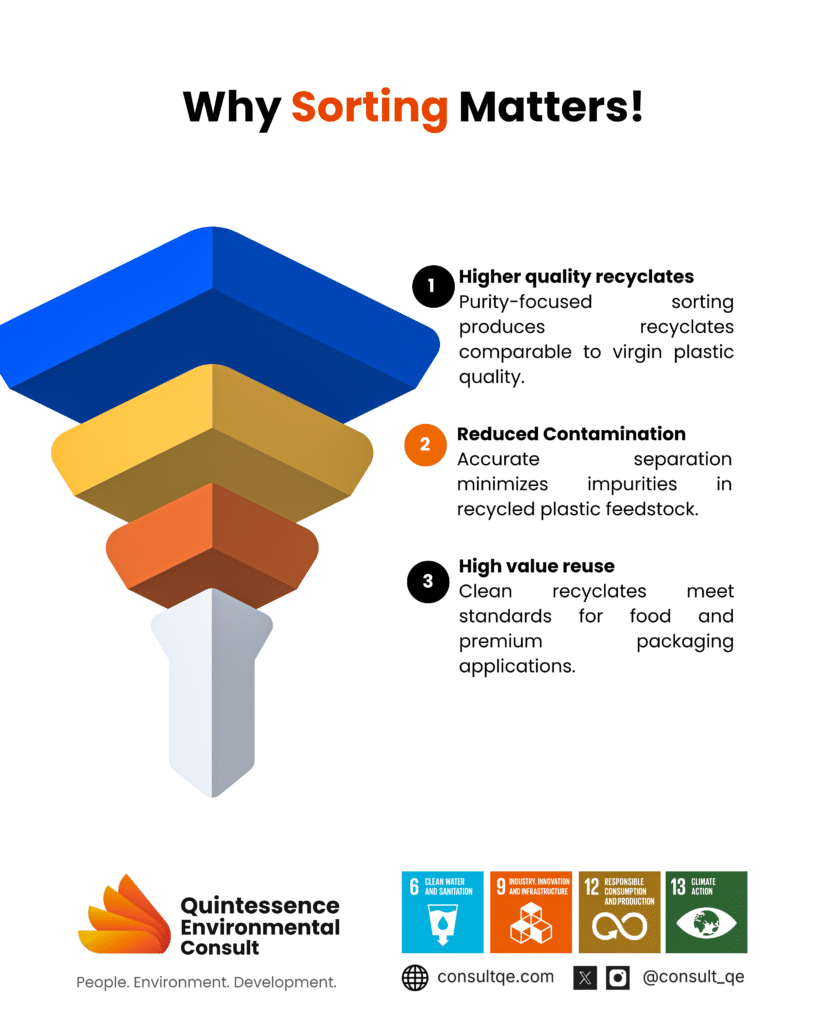

The pursuit of efficient and accurate sorting technology led to the conceptualization of Holy Grail 1.0. Driven by the Ellen MacArthur Foundation’s New Plastics Economy program. Launched in 2016, the initiative brought together 40 leading companies and cities to explore innovative circular economy approaches for plastics. The program’s outcome, concluding in 2019, was a groundbreaking project codenamed Holy Grail 1.01.

Holy Grail 1.0 served as a proof of concept for a revolutionary digital technology for plastic sorting, “digital watermarking”. This innovation allows for the embedding of invisible watermarks across the entire surface of packaging, without interfering with its design or labeling. These watermarks are undetectable to the human eye but can be identified using high-resolution cameras. Once detected, they provide crucial digital data, such as the specific type of material used. As an upstream solution, Holy Grail 1.0 aimed to enhance the efficiency of downstream processes like collection, sorting, and recycling, ultimately leading to higher-quality recycled materials1.

HOLY GRAIL 2.0: FROM CONCEPT TO COMMERCIAL REALITY

Building on the success of the Holy Grail 1.0 proof of concept, and fueled by ambitious EU extended producer responsibility targets to ensure 100% of plastic packaging is reusable, easily recyclable, or compostable by 2030, over 130 companies joined forces under the leadership of the European Brand Association AIM to launch Holy Grail 2.0. This ambitious project received significant financial backing from the Alliance to End Plastic Waste (AEPW).

Holy Grail 2.0 represents an intelligent sorting technology co-developed by machine vendor Pellenc ST and digital watermarks technology supplier Digimarc. This follow-up project was meticulously designed in three progressive stages:4

- Development of prototype detection units: Creating the initial hardware for watermark identification.

- Semi-industrial trials: Testing the technology in a controlled, yet larger-scale environment.

- Industrial trials: Implementing and evaluating the technology under real-world, routine industrial conditions.

Key Gains of Holy Grail 2.0: A Paradigm Shift in Sorting

The industrial trials of Holy Grail 2.0 have yielded impressive results, demonstrating its potential to revolutionize plastic recycling:

- High Detection Rate: Trials at the Hündgen Entsorgung material recovery facility in Germany showcased remarkable detection rates. Over a 100-day period, nearly 56,000 items were processed daily, with detection rates consistently ranging between 87.9% and 93.8%1. This level of accuracy is unprecedented in large-scale plastic sorting.

- Enhanced Sorting Purity: The technology was tested on post-consumer rigid packaging waste across various plastic types and formats, including four rigid plastics (PET non-food bottles, rigid PP, rigid PE, and PET trays) and two flexibles (PP flexibles and LDPE flexibles). It consistently achieved high purity rates of 95% on average under routine industrial conditions, even with soiling and crushing of materials. This high purity is critical for creating valuable, high-quality recyclates.

- High Sorting Speed: Holy Grail 2.0 was rigorously tested at a belt speed of 3 meters per second, simulating typical industrial operations with inherent soiling and crushing. Crucially, when the sorting was tested at an even higher belt speed of 4.5 meters per second, no loss of performance was observed, even with severe soiling and crushing. This high-speed capability is vital for processing the massive volumes of plastic waste generated daily.

- Commercial Viability: With the successful conclusion of the industrial trials, the next crucial stage for Holy Grail 2.0 is market adoption. A pilot market launch is slated for France in 2024, involving major global brands such as Henkel, L’Oréal, and Procter & Gamble under the “Holy Grail 2030 – Circular Packaging” initiative. The primary objective of this pilot is to unequivocally prove the economic viability of smart sorting and the subsequent reprocessing of sorted plastics into high-quality recyclates1. This step is crucial for widespread implementation and realizing the full potential of the technology.

IMPLICATIONS FOR RECYCLING IN NIGERIA

While HolyGrail 2.0 is an EU-driven initiative, its transformative potential extends globally, offering a robust framework for adoption and domestication in countries like Nigeria to significantly enhance recycling efforts. Implementing digital watermarking technology could dramatically improve the efficiency of local recycling facilities, drastically reduce contamination in recycled materials, and, most importantly, accelerate the development of a circular economy within the nation.

Furthermore, this technology can facilitate a more effective implementation of Extended Producer Responsibility (EPR) schemes in Nigeria. By enabling the accurate determination of plastic source through digital watermarks, producers can be held more directly accountable for the end-of-life management of their products.

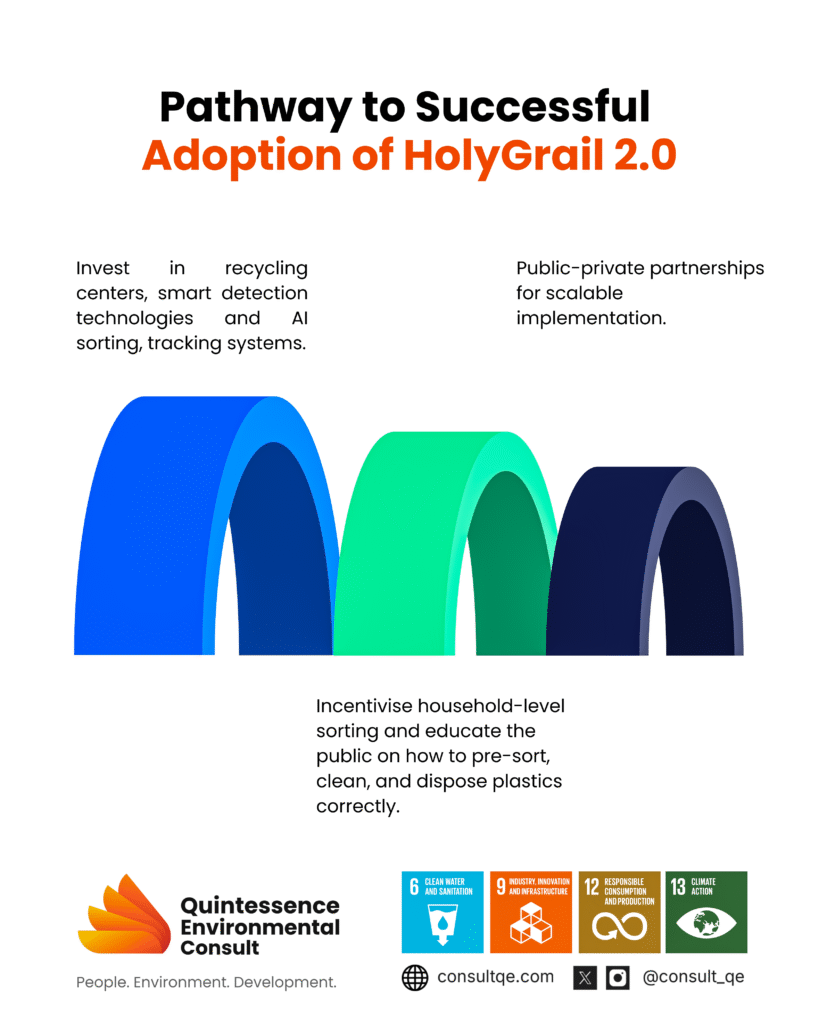

However, successful adaptation in Nigeria would necessitate significant investment in infrastructure and technological development. This includes setting up the necessary detection systems at recycling centers and potentially integrating them into existing waste management frameworks. Crucially, stakeholder collaboration, particularly with private companies that produce or extensively use plastic packaging, is essential for a seamless transition and widespread adoption of this cutting-edge technology.

CONCLUSION

Major cities in Nigeria (Lagos, Kano, and Abuja) face major waste challenges due to their massive populations, urbanization, and high/commercial activity, generating thousands of tonnes daily as well as Port Harcourt, Ibadan, and Onitsha, with industrial streams and robust informal networks, show strong recycling potential.

Proper sorting is not merely a desirable step; it is a critical requirement for achieving efficient and higher-quality plastic recycling. The Holy Grail 2.0’s digital watermarking technology represents a monumental leap forward, demonstrating significant improvements in the accuracy and efficiency of plastic sorting. Its proven capabilities offer a viable pathway to unlock the true potential of plastic recycling, transforming waste into valuable resources.

The successful implementation of Holy Grail 2.0 in pilot markets could serve as a powerful model for other regions worldwide, including Nigeria, inspiring and guiding them to enhance their recycling systems and contribute meaningfully to global sustainability goals. This technology isn’t just about recycling; it’s about fundamentally reshaping our relationship with plastic and moving towards a sustainable circular future.

NB: video showing the demonstration of the technology.

REFERENCES

- AIM-Europe Brand Association. (n.d.). Holy Grail 2.0: Pioneering Digital Watermarks. Retrieved July 9, 2025, from https://www.digitalwatermarks.eu/

- Brouwer, M. T., Thoden van Velzen, E. U., Ragaert, K., & ten Klooster, R. (2020). Technical Limits in Circularity for Plastic Packages. Sustainability, 12(23), 10021. https://doi.org/10.3390/su122310021

- Geyer, R., Jameck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782. https://doi.org/10.1126/sciadv.17007F82

- Müller-Kirschbaum, T., & Trombetti, M. (2025, June 27). HolyGrail 2.0: Intelligent Sorting Through Digital Watermarks. In Proceedings of the 27th International Conference on Plastics Recycling (pp. 1047–1054). https://doi.org/10.1007/978-3-031-66209-6_54

- Ruj, B., Kumar, S., & Shamim, S. (2015). Sorting of plastic waste for effective recycling. International Journal of Applied Sciences and Engineering, 4(4), 45–52.

- HolyGrail 2.0 Digital Watermarking. (2024, November 6). Vimeo.